yeah, Ive no idea what the calibration is for either…

you’d think mainly it would cover ‘manufacturing’ tolerances within the key mechanism, but that would be fairly ‘fixed’ after construction.

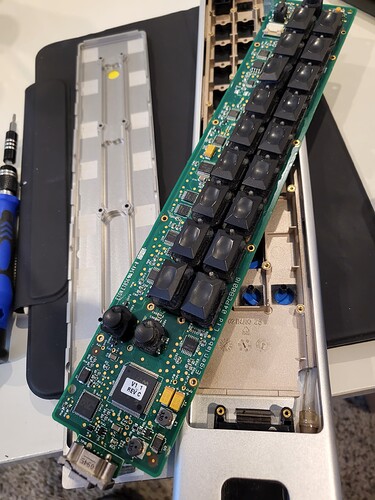

that said, Ive not see the key mechanism, but I now others here have… as they showed at the EigenLabs ‘dev con’ one year (before my time unfortunately) … there they were shown in pieces, so perhaps they are not one solid piece… but again, would taking apart (carefully) really alter their characteristics?

my only thought is perhaps something changes vert slightly as they are mounted/supported in the case, which can make tiny changes? but its all pure speculation.

so I don’t really know,

it’s not uncommon for manufactures to try to dissuade users to not take apart devices…

partly because some can be a bit ‘clumsy’ or just not take necessary precautions, and unfortunately the some will then expect the manufacturer to fix their mistakes.

so perhaps this is the case here.

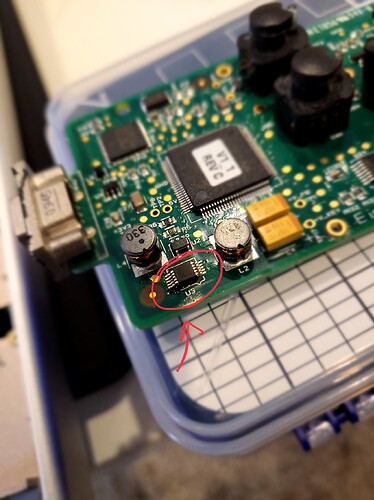

however, in this particular case, EigenLabs were very explicit about the issue of calibration, and the necessity of using a the hardware jig to recalibrate.

I guess what we really don’t know is … does dis-assembly 100% mean mis-calibration, or does it cause possible mis-calibration… and if so what preventative measures can be taken.

for sure, this is a concern long term.

whilst John/EigenLabs have been really great at continuing to service Eigenharps, that cannot happen forever … and no-one else has the jig (*) necessary to do this calibration

(*) apparently the jig is pretty complex, from what I understand, basically holds Eigenharp in places and presses keys very precisely, while communicating with the software of the Eigenharp to get its readings.

so, knowing what force you apply, and what it reads would lead to calibration data.

given the sensitivity of the eigenharp keys, these exertions of pressure must be exceedingly precise.

so unfortunately, very much a custom bit of gear that would be very hard to reproduce even if we had the specifications and process (**) … which we do not

(**) I should say, as far as I know, no-one has ever approached John/Eigenlabs about this, so there is a possibility they’d be happy to share details, find a solution. but honestly, thats only really viable for another instrument manufacturer … rather than a musicians/developer.